Experienced in Mechanical, Chemical, Metallurgical, And Corrosion Testing

News

November 2020

Philip Schreiner Appointed Analytical Lab Manager

Metallurgical Lab

Tensile Testing Metallurgical Laboratory is pleased to announce the addition of Philip Schreiner to its staff as Analytical Lab Manager. With him, Phil brings over 23 years of laboratory experience - 19 years in Metallurgical Materials Testing, Inspection, and Laboratory Management.

Chemistry: OES & Leco

With experience in Metallurgical Testing, Chemical Analysis and Mechanical Testing he has serviced and built relationships within the Aerospace, Automotive, Nuclear, Automotive and Commercial/Industrial industries.

Relationships are key to organic growth, and Phil is looking forward to driving this growth by effectively and efficiently serving our customers while working for Tensile Testing Metallurgical Laboratory.

October 2020

New Horizonal Tensile Test

New Horizonal Tensile Test

Tensile Testing Metallurgical Laboratory (TTML) obtained a new horizonal Tensile Tester doubling capacity for testing Flat Tensiles including ASTM, JIS, DIN, and R & N VALUES

Along with the Waterjet used for sample prep, Tensile Testing has improved the turn time. Samples can be pulled up to 400K material.

May 2019

System for Award Management (SAM)

Adams, J T Co (Inc) – Tensile Testing / 004202685 / 47513 was registered and is now active in the U.S. federal government's System for Award Management (SAM).

April 2019

ISO/IEC 17025 from A2LA Valid to May 31, 2021

Tensile Testing was audited to the new 17025:2017 and successfully achieved technical competence in Chemical and Mechanical Testing. Also included in this accreditation is meeting the requirements of R223 – Specific Requirements: GE Aviation S400 Accreditation Program. Please see the new Scope of Accreditation which was extended to May 31, 2021:

http://www.tensile.com/pages/certifications.htm

Feb 2019

Welcome Matthew E. Gaydos, CWI

Tensile Testing Metallurgical Laboratory is pleased to announce the addition of Matthew E. Gaydos to its staff as a Certified Welding Inspector (CWI). Matt will oversee Tensile Testing's routinely performed tests on welded plates and tubes in accordance with ASME & AWS:

- Procedure Qualification Record (PQR)

- Welding Procedure Specifications (WPS)

Matt is available to audit, inspect and review your materials for quality assurance. Please give him a call (216) 641-3290.

January 2019

Tensile Testing Celebrating 40 Years

Tensile Testing was founded in 1979 as the Metallurgical Laboratory complement of the machining side of J. T. Adams Co. Inc. the fabrication and testing needs of the metal industries of Northeast Ohio. Since that time it has grown to over 40 employees and is located in Cleveland in its 37,500 sq. ft. facility. We are here to meet all your mechanical, chemistry, metallurgical, corrosion testing. Give us a call (216) 641-3290 or email us at sales@tensile.com.

December 2019

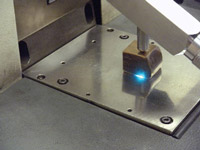

New Leco Hydrogen, Oxygen, and Nitrogen Analyzer

Tensile Testing purchased a new Leco Analyzer capable of doing the gases: Hydrogen, Oxygen, and Nitrogen. This machine is a complement to our OES and Leco Carbon & Sulfur analyzers.

November 2018

Nuclear

Tensile Testing has been qualified as a nuclear supplier through a 'NUPIC-style' Commercial Grade Survey, performed by the First Energy Nuclear Operating Company. Interested parties can obtain the audit report by contacting FENOC directly.

Tensile Testing Metallurgical Laboratory is a "Commercial Grade Supplier" to the Nuclear Industry having gone through several associated audits. TTML adheres to the applicable requirements of 10 CFR 21 and 10 CFR 50 Appendix B.

TTML continues to meet the requirements of ISO/IEC 17025:2005, the Nuclear Industry Standard.

June 2018

ACCEPTANCE CRITERIA FOR EXPANSION BOLTS IN STRUCTURAL STEEL CONNECTIONS (BLIND-BOLTS) (AC437)

Tensile Testing has added testing to ICC AC437 which includes Static Tension Test and Static Shear Test to its Scope of Accreditation. For more Fastener Testing please give us a call.

May 2018

Fastener Testing

Tensile Testing attended the Fastener Fair April 11 & 12 in Cleveland. This was the first time for the show and as an exhibitor we were pleased to participate.

There were 2,000 registrants consisting of professionals from the entire supply chain with over 250 exhibitors from 20 countries that represented a variety of industries like distribution, automotive, aerospace, energy, civil engineering, and construction.

Tensile Testing offers common Fastener Tests on Bolts, Nuts, Washers, etc.:

- Wedge / Axial

- Proofload

- Charpy V-Notch

- Clamp Load

- Cone Strip

- Drive Test

- Hardness (Core / Surface)

- Shear (Single / Double)

- Torque Tests

- 24 Hour Heat Treat w/Hardness

- Chemistry (OES & Leco)

- Decarb / Grain Size

- Hydrogen Embrittlement

- Rotational Capacity (Rocap)

- Salt Spray

- SEM / Failure Analysis

- Stress Durability

- Tensiles (Machined)

May 2018

Nadcap Valid to April 30, 2020

To demonstrate their continued commitment to quality, Tensile Testing Metallurgical Laboratory (TTML) announces that they have been successful in achieving continued Nadcap accreditation for Materials Testing extending to April 30, 2020.

"It was a long five-day audit process and I am proud of the performance of all of our departments that played a role in the audit" said Quality Manager Alex Manuk.

The aim of the Nadcap program is to assess process capability for compliance to industry standards and customer requirements. By achieving Nadcap accreditation, TTML has demonstrated their compliance.

"Compliance via Nadcap accreditation is a milestone in demonstrating manufacturing excellence." said Joe Pinto, Executive Vice President and Chief Operating Officer at the Performance Review Institute. "By obtaining Nadcap in Materials Testing, TTML have proved to the industry that they are committed to quality and aerospace safety."

TTML has been continuously Nadcap accredited for Materials Testing since 2003. This accreditation covers the laboratory's wide scope of destructive testing services that are required by the aerospace and defense industries to support material development, material selection, and manufacturing.

April 2017

ISO/IEC 17025 from A2LA Valid to May 31, 2019

Tensile Testing Metallurgical Laboratory (TTML) successfully completed the ISO/IEC 17025:2005 assessment and obtained the updated Scope of Accreditation from American Association for Laboratory Accreditation (A2LA) which is extended to May 31, 2019.

May 2015

ISO/IEC 17025 from A2LA Valid to May 31, 2017

Tensile Testing Metallurgical Laboratory (TTML) successfully completed the ISO/IEC 17025:2005 assessment and obtained the updated Scope of Accreditation from American Association for Laboratory Accreditation (A2LA) which is extended to May 31, 2017.

January 2015

Celebrating 60 years in Business

In 1955 Joseph Adams founded the J.T. Adams Company to meet the needs of Cleveland area manufacturers. Opening his tool and cutter grinding shop, Mr. Adams soon developed business relationships with forging, casting, and manufacturing companies in the local area.

In 1979 the Tensile Testing Division came into being to meet the fabrication and testing needs of the metal industries of Northeast Ohio.

In 2005, after 50 years in Cleveland, Tensile Testing Metallurgical Laboratory (TTML) moved the entire company to 4520 Willow Parkway into the current 37,000 sq ft facility accommodating a growing staff and full-line commercial laboratory specializing in the delivery of cost-effective, high quality, timely specimen fabrication, and analytical services to a wide variety of markets.

Feb 2014

Welcome Michael Gaydos

Tensile Testing Metallurgical Laboratory is pleased to announce the addition of Michael Gaydos to its staff as Business Development Manager.

Mike brings 53 years experience in the Metallurgical Materials Testing and Inspection Industry.

With experience in Mechanical Testing, Chemical Analysis, Metallurgical Evaluations, and Non-Destructive Inspection he serviced the Commercial, Automotive, Aerospace, and Nuclear Industries developing long lasting relationships.

Test methods, material specifications interpretation, and business development are key areas Mike is now looking forward to continue while working for Tensile Testing Metallurgical Laboratory.

Contact Mike at (216) 641-3290

Fax: (216) 641-1223

MikeG@tensile.com